薄膜的應(yīng)力控制技術(shù)研究現(xiàn)狀

摘 要:薄膜應(yīng)力普遍存在于薄膜元器件中,從而影響薄膜器件性能,限制了其良好的應(yīng)用前景.所以控制薄膜的應(yīng)力,消除其不良影響,是薄膜生產(chǎn)工藝中不可或缺的技術(shù)手段.本文對(duì)此詳細(xì)闡述了幾種常用的薄膜應(yīng)力控制方法,并對(duì)以后研究工作的開(kāi)展提出幾點(diǎn)要求.

關(guān)鍵詞:薄膜;應(yīng)力;控制技術(shù)

分類號(hào):O484.2 文獻(xiàn)標(biāo)識(shí)碼:A

文章編號(hào):1672-7126(2008)增刊-017-05

Stress Release and Control of Thin Films materials Used in Devices Fabrication

Jiang Zhao Chen Xuekang

蔣釗,聯(lián)系人:Tel:13893225634;E-mail:qqq-128@163.com

作者單位:蔣釗(蘭州物理研究所,表面工程技術(shù)國(guó)家級(jí)重點(diǎn)實(shí)驗(yàn)室,蘭州,730000)

陳學(xué)康(蘭州物理研究所,表面工程技術(shù)國(guó)家級(jí)重點(diǎn)實(shí)驗(yàn)室,蘭州,730000)

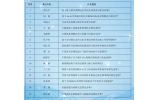

參考文獻(xiàn):

[1]范瑞瑛,范正修.薄膜應(yīng)力分析及一些測(cè)量結(jié)果.光學(xué)儀器,2001,23(5-6):84-96

[2]范玉殿,周志峰.薄膜內(nèi)應(yīng)力的起源.材料科學(xué)與工程,1996,14(1):5-12

[3]卜錦鑫.碟形熱雙金屬片曲率和溫度的關(guān)系.低壓電器,2000,1:53-55

[4]范玉殿,周志峰.薄膜熱應(yīng)力的研究.真空科學(xué)與技術(shù)學(xué)報(bào),1996,16(5):347-353

[5]Oliveira J C and Cavaleiro A.Influence of substrate properties and annealing temperature on the stress state of magnetron sputtered tungsten thin films.J Vac Sci Technol,2006,A 24(6):2071-2075

[6]宋學(xué)萍,周桃飛,趙宗彥,等.退火溫度對(duì)濺射Al膜微結(jié)構(gòu)及應(yīng)力的影響.材料科學(xué)與工程,2003,21(5):724-726

[7]安兵,張同俊,袁超,等.對(duì)Ag/Cu薄膜退火應(yīng)力的模擬.材料研究學(xué)報(bào),2003,17(5):460-464

[8]Tbeuless M D,Gupta J,Harper J M E.Stress development and relaxation in copper films during thermai cycling.J Master Res,1993,8(8):1845

[9]Keller R M,Baker S P,Arzt E.Stress-temperature behavior of unpassivated thin copper films.Aeta Master,1999,47(2):415

[10]Zhang X,Cben K S,Spearing S M.Themro-mechanical behavior of thick PECVD oxide films for power MEMS applications[J].Sensors and Actuators,2003,A 103:263-270

[11]程開(kāi)甲,程漱玉.薄膜內(nèi)應(yīng)力的分析和計(jì)算.自然科學(xué)進(jìn)展.1998,8(1):21-22

[12]程開(kāi)甲,程漱玉.電子邊界是決定分子間作用特性的重要條件.科技導(dǎo)報(bào),1993,12:30

[13]程開(kāi)甲,程漱玉.TFD模型和余氏理論對(duì)材料設(shè)計(jì)的應(yīng)用.自然科學(xué)進(jìn)展,1993,3(5):417

[14]劉繼峰,馮嘉酞,朱靜.CoSi2薄膜內(nèi)應(yīng)力的微觀機(jī)制研究.自然科學(xué)進(jìn)展,2001.11(2):163-167

[15]王若楠,劉繼峰.C+離子注入對(duì)CoSi2薄膜應(yīng)力的研究[J].自然科學(xué)進(jìn)展2002,12(12):1296-1300

[16]Kupfer H,Flugel T,Richter F,et al.Opertical properties and mechanical stress in SiO2/Nb2O5 multilayers.Thin solid films,2001,389:278-283

[17]Hoffman D W.Perspective on stresses in magnetron-sputtered thin films.J Vac Sci.Technol.1994,A12(4):953-961

[18]邵淑英,范正修,邵建達(dá).ZrO2薄膜應(yīng)力實(shí)驗(yàn)研究.光學(xué)學(xué)報(bào),2004,24(5):437-411

[19]邵淑英,范正修,范瑞瑛,等.沉積溫度對(duì)ZrO2薄膜性質(zhì)的影響.中國(guó)激光,2004,31(6):701-704

[20]范玉殿,周志峰.薄膜濺射沉積過(guò)程中的原子噴丸效應(yīng).真空科學(xué)與技術(shù)學(xué)報(bào),1996,16(4):235-241

[21]Vink T J,Walrave W,Daams J L C,et al.Stress,strain and microstructure in thin tungsten films deposited by de magnetron sputtering.J.Appl Plays,1994,74(2):988-994

[22]Satomi N,Kitamura M,Sasaki T,et al.Internal stress control of benin thin film.Fusion engineering and design,1998,39-40:493-497

[23]Hoffman D W.Internal stress in sputtered chromium.Thin solid films,1977,40:355

[24]Cuomo J J,Harper J M E,Guamieri C R.Modification of niobium film stress by low-energy ion bombardment during deposition.J Vae Sci.Technol,1982,20:349-354

[25]呂學(xué)超,汪小琳,鮮曉斌,等.偏壓對(duì)鈾上磁控濺射鋁鍍層微結(jié)構(gòu)及殘余應(yīng)力的影響.原子能科學(xué)技術(shù),2003,37:122-123